Every year, millions of electric vehicle (EV) batteries eventually reach the end of their lifespan, presenting both an environmental challenge and an opportunity. With an increasing number of EVs on the roads, the question of how to effectively recycle these batteries becomes imperative. The process not only reduces waste but also recovers valuable metals like lithium, cobalt, and nickel.

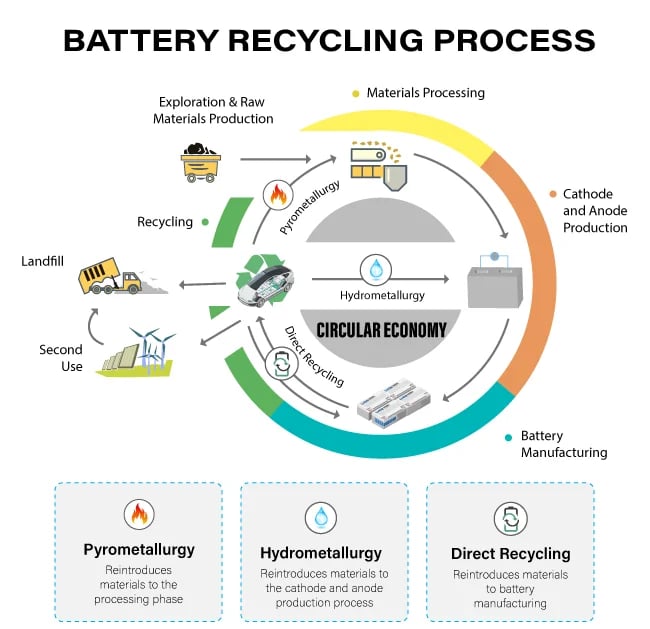

EV battery recycling involves several critical steps. First, the batteries are collected and sorted, followed by a discharge process to ensure safety. Technologies such as hydrometallurgy and pyrometallurgy are then employed to extract and purify the metals. A remarkable fact is that up to 95% of the materials in EV batteries can be reclaimed and reused, showcasing both the efficacy and potential of modern recycling methods.

EV batteries are recycled through a multi-step process involving discharging to remove electrical energy, dismantling to separate components, and sorting materials. Hydrometallurgical and pyrometallurgical methods extract valuable metals like lithium, cobalt, and nickel. Direct recycling further refurbishes battery components for reuse, maximizing material recovery and minimizing environmental impact.

How Are EV Batteries Recycled

Recycling EV batteries involves several steps to ensure safety and efficiency. First, the batteries are collected from various sources, including end-of-life vehicles and manufacturing waste. They then undergo a discharge process to remove any remaining electrical energy, making them safe to handle. The next stage is dismantling, where the battery packs are taken apart. This separation allows for the individual components to be processed appropriately.

Once the batteries are dismantled, they go through a sorting process. This is where the valuable metals, such as lithium, cobalt, and nickel, are separated for recovery. One common method is hydrometallurgy, where the metals are dissolved in a chemical solution and then extracted. Pyrometallurgy, involving high temperatures, is another method used to reclaim these metals. These processes ensure that we can reuse these materials in new batteries.

Newer technologies are emerging to improve this process further. Direct recycling aims to recondition and reuse battery components without breaking them down fully. This method can save a lot of energy and resources. Innovations like these make battery recycling more sustainable and less costly.

Effective recycling of EV batteries brings several benefits. It reduces the demand for new raw materials and minimizes waste. Additionally, it lessens the environmental impact caused by mining activities. The recovered metals can be used to make new batteries, creating a circular economy. This ensures a more sustainable future for both the electric vehicle industry and the planet.

Why It’s So Hard To Recycle Electric-Car Batteries | World Wide Waste

Process Overview: From Collection to Material Recovery

The first step in recycling EV batteries is collecting them from various sources. These sources include old electric vehicles, discarded battery packs, and even defective batteries from manufacturers. Once collected, the batteries are stored safely until they can be processed. Proper storage is crucial to prevent any potential hazards. This ensures they remain safe and intact before recycling.

Next, the batteries undergo a thorough discharge process. This step removes any lingering electric charge, making them safe to handle. After discharging, the batteries are then dismantled carefully. Each component, such as the cells and modules, is separated out. This disassembly allows for a more efficient recycling process.

The dismantled components are then sorted based on material type. Metals like lithium, cobalt, and nickel are separated from plastics and other elements. Various methods, such as hydrometallurgy and pyrometallurgy, help extract these valuable metals. Hydrometallurgy uses chemical solutions, while pyrometallurgy involves high temperatures. These techniques ensure that the maximum amount of material can be recovered.

Finally, the recovered materials are processed and refined. These purified metals can be reused in the production of new batteries. This not only conserves natural resources but also reduces the environmental impact. By reusing materials, the battery recycling process supports a circular economy. This method emphasizes sustainability and efficiency, making it beneficial for everyone.

Discharging and Dismantling: Safety First

Discharging EV batteries is a critical initial step in the recycling process. This procedure effectively eliminates the remaining electrical energy stored in the battery. It’s a necessary precaution to prevent any accidents during dismantling. Technicians use specialized equipment to safely discharge the energy. This ensures the battery is inert and safe for further handling.

After discharging, the next step is dismantling the battery. This process involves taking the battery apart to separate its components. It’s not as simple as it seems, as EV batteries are complex structures. Each part, from the cells to the casing, needs to be carefully removed. This careful dismantling helps to preserve the integrity of reusable materials.

Safety is a top priority during both discharging and dismantling. Workers wear protective gear to guard against hazardous materials. The recycling facilities also follow strict safety protocols. This reduces the risk of exposure to dangerous substances. These measures ensure a safe working environment.

Efficient discharging and dismantling set the stage for successful material recovery. Once the battery is completely dismantled, valuable metals and other components are extracted. These recovered materials can then be purified and reused. By focusing on safety first, the recycling process becomes more effective. It ensures that valuable resources are recovered without compromising worker safety.

Sorting and Separation: Extracting Valuable Components

After the discharging and dismantling steps, sorting and separation become the focus. This phase is crucial for recovering valuable materials like lithium, cobalt, and nickel. The dismantled components are sorted based on their material types. Advanced machinery helps to identify and separate different materials efficiently. This sorting ensures that each type of material can be processed appropriately.

Separation techniques vary depending on the material. For metals, hydrometallurgical processes are commonly used. This involves dissolving the metals in a chemical solution to extract them. Another method, pyrometallurgy, uses high temperatures to melt and separate the metals. Both methods are effective, but hydrometallurgy is often preferred for its lower energy requirements.

Once extracted, the materials must be purified. This step ensures that only high-quality components are recovered. Purification removes any impurities that might have mixed with the metals during the sorting process. The goal is to achieve a purity level that allows the materials to be reused in new batteries. This helps create a sustainable cycle of materials reuse.

In addition to metals, other components like plastics and electrolytes are also separated. These materials don’t go to waste either. They are recycled separately and can be reused in various industries. By sorting and separating all components, the recycling process maximizes resource recovery.

Successful sorting and separation reduce the need for new raw materials. By reclaiming and reusing existing materials, we reduce environmental impact. This leads to less mining and fewer emissions. Effective recycling practices contribute to a greener and more sustainable future. It’s a win-win for both the industry and the planet.

Hydrometallurgical Process: Chemical Solutions at Work

The hydrometallurgical process is a vital part of recycling EV batteries. This method uses chemical solutions to extract metals from the dismantled battery components. Initially, the metals are dissolved in acid, creating a solution. This solution is then subjected to various treatment steps to recover the metals. The process is efficient and can be done at room temperature.

This approach has several advantages over other methods. It requires less energy compared to high-temperature processes like pyrometallurgy. The use of chemicals allows for precise extraction of specific metals. For instance, lithium and cobalt can be individually targeted and recovered. This precision makes hydrometallurgy highly effective for recycling complex battery materials.

The extracted metals undergo purification to remove any remaining impurities. Techniques such as solvent extraction and precipitation are employed. These ensure that the metals are of high quality, ready for reuse. The purified metals are then transformed into usable forms. They can be utilized in the production of new EV batteries.

Another benefit of hydrometallurgy is its environmental impact. The process generates fewer emissions and less waste. Reusing the chemical solutions further minimizes its environmental footprint. This makes it a sustainable option for recycling. By adopting hydrometallurgy, the battery recycling industry can reduce its ecological impact significantly.

Hydrometallurgy isn’t limited to EV batteries alone. The same principles can be applied to other waste streams. This versatility enhances its value in various recycling applications. As technology advances, the efficiency of hydrometallurgical processes continues to improve. The future holds even greater potential for this innovative recycling method.

Pyrometallurgical Process: High-Temperature Recycling

Pyrometallurgical recycling involves using high temperatures to recover valuable metals from EV batteries. In this process, the batteries are subjected to extreme heat in a smelting furnace. The intense heat breaks down the battery materials, allowing the metals to melt and separate. This method is particularly effective for extracting metals like cobalt, nickel, and copper. Once separated, these metals can be collected and refined for reuse.

The process has a few distinct advantages. One major benefit is its ability to handle large volumes of battery waste simultaneously. The high temperatures ensure that even complex mixtures of materials are effectively processed. This makes pyrometallurgy suitable for large-scale recycling operations. Another advantage is the thorough recovery of metals, leaving minimal waste behind.

While effective, pyrometallurgy also has its challenges. The energy requirements are significantly high due to the extreme temperatures needed. This can result in higher operational costs and larger carbon footprints. However, advancements are being made to improve the energy efficiency of the process. Some facilities use energy recovery systems to minimize waste and reduce overall consumption.

Despite these challenges, pyrometallurgical recycling remains an important method. It plays a crucial role in reducing reliance on freshly mined metals. By recycling metals already in use, we reduce the need for additional mining. This helps in mitigating the environmental impact associated with extracting new materials. The process contributes to a more sustainable lifecycle for EV batteries.

To sum up, the pyrometallurgical process is a robust and efficient method for recycling EV batteries. Its high-temperature approach ensures complete recovery of valuable metals. Though it requires significant energy, ongoing improvements aim to make it more sustainable. This method is essential for the successful recycling and reuse of battery materials.

Direct Recycling: A New Frontier in Battery Reuse

Direct recycling represents an innovative approach to battery reuse. Unlike traditional methods, it aims to recover and reuse the battery materials without breaking them down completely. This process keeps the original structure of the battery materials intact. It allows for significant savings on energy and resources. By focusing on reconditioning, direct recycling brings us closer to a circular economy.

The key advantage of direct recycling is its efficiency. Since there is no need to fully dismantle or melt down the batteries, less energy is consumed. This method can also be faster compared to other processes like hydrometallurgy or pyrometallurgy. Efficiency means lower costs and reduced environmental impact.

Several steps are involved in direct recycling. The used battery materials are first collected and assessed for their condition. Then, specific rejuvenation techniques are applied to restore their functionality. Depending on the battery type, this might involve reactivating the electrochemical properties or simply cleaning the components. The goal is to bring these materials back into a state where they can be used again.

Moreover, direct recycling has its own set of challenges. One major hurdle is ensuring that the rejuvenated materials meet strict quality standards for new batteries. Consistency and reliability are crucial for safety reasons. Innovations in technology aim to address these concerns, making direct recycling more viable over time.

This emerging method holds great promise for a more sustainable future. By reducing waste and conserving raw materials, direct recycling aligns well with global sustainability goals. As research continues, we can expect improvements in both efficiency and effectiveness.

The Importance of Recycling EV Batteries

Recycling EV batteries is crucial for several reasons, particularly as the world shifts towards electric vehicles. One of the main reasons is environmental protection. EV batteries contain toxic substances that can harm ecosystems if disposed of improperly. Recycling helps prevent harmful chemicals like lithium and cobalt from contaminating soil and water. Ensuring proper disposal reduces these risks significantly.

Another important aspect is resource conservation. The materials used in EV batteries, such as nickel, cobalt, and lithium, are finite resources. By recycling, we can recover these valuable materials and use them again. This reduces the demand for new mining activities. It helps in conserving natural resources and minimizes environmental degradation.

Economic benefits also play a significant role. The recycling industry creates job opportunities and stimulates economic growth. Recovered materials can be sold and reused, adding value to the economy. Recycling reduces manufacturing costs for new batteries as reclaimed materials are often cheaper than freshly mined ones. This makes EVs more affordable for consumers.

Moreover, recycling supports technological advancements. Research into more efficient recycling methods pushes the boundaries of science and technology. These advancements can lead to the development of better and more sustainable battery technologies. Encouraging recycling can drive innovation in battery design and manufacturing.

Finally, recycling EV batteries aligns with global sustainability goals. It promotes a circular economy where materials are continuously reused. This reduces waste and conserves resources for future generations. By emphasizing recycling, we contribute to a cleaner, more sustainable planet. It’s a necessary step towards a greener future.

Environmental Benefits of Proper Battery Disposal

Proper disposal of EV batteries offers significant environmental benefits. One key advantage is the reduction of harmful chemicals in the environment. Batteries contain heavy metals and toxic substances that can leach into soil and water if not disposed of correctly. These pollutants can harm wildlife and contaminate drinking water sources. Proper disposal prevents these issues and protects ecosystems.

Another benefit is the conservation of natural resources. By properly disposing of and recycling batteries, valuable metals like lithium and cobalt can be recovered. This reduces the need for new mining activities. Mining often leads to deforestation, habitat destruction, and soil erosion. Recycling reduces the environmental footprint associated with extracting these raw materials.

Proper disposal also contributes to a decrease in greenhouse gas emissions. Manufacturing new batteries from raw materials consumes a lot of energy and emits a significant amount of carbon dioxide. Recycling used batteries requires less energy and generates fewer emissions. This helps in combating climate change and reducing air pollution.

Additionally, proper disposal helps prevent electronic waste (e-waste) from accumulating in landfills. E-waste is a growing problem worldwide and poses serious environmental threats. When batteries end up in landfills, they can release harmful substances over time. Proper disposal practices ensure that batteries are processed safely and responsibly.

A final benefit is the promotion of sustainable practices. By encouraging proper battery disposal, we support a circular economy. This approach focuses on reusing and recycling materials rather than relying on continuous extraction. It drives innovation in recycling technologies and promotes environmental stewardship. Proper disposal practices ensure a cleaner and more sustainable future for everyone.

Technological Innovations in EV Battery Recycling

Technological innovations are transforming EV battery recycling, making it more efficient and environmentally friendly. One major advancement is the development of automated disassembly systems. These machines can quickly and safely dismantle battery packs, separating valuable components. Automation reduces labor costs and increases the recycling throughput. It also minimizes human exposure to hazardous materials.

Another significant innovation is improved hydrometallurgical methods. Researchers are developing new chemical solutions that are less toxic and more effective. These solutions can recover metals with higher purity levels. They also work more quickly than traditional chemicals. This advancement makes the recycling process faster and safer for the environment.

Direct recycling technologies are also gaining attention. These methods focus on reconditioning and reusing battery materials without completely breaking them down. Innovations in this area have led to techniques that can restore the functionality of used battery components. This approach saves energy and preserves the original chemical structure of the materials. Direct recycling is seen as a promising solution for sustainable battery reuse.

The use of artificial intelligence (AI) and machine learning is enhancing recycling processes as well. AI can optimize the sorting and separation of materials, ensuring higher efficiency. Machine learning algorithms help predict the best recycling methods for different types of batteries. These technologies improve the precision and effectiveness of recycling operations.

Furthermore, advancements in material science are contributing to better recycling methods. Scientists are developing new battery designs that are easier to recycle. These designs include batteries with fewer toxic materials and more recyclable components. By making batteries more sustainable from the start, the entire lifecycle becomes more eco-friendly.

Overall, these technological innovations are making EV battery recycling more efficient, cost-effective, and environmentally sustainable. They are paving the way for the future of recycling, ensuring that we can continue to benefit from electric vehicles without harming the planet. Continuous research and development will likely bring even more breakthroughs in the years to come, further improving recycling processes and outcomes.

Economic Impact of Recycled Materials from EV Batteries

The economic impact of recycling EV batteries is significant. One major benefit is the reduction in manufacturing costs for new batteries. Recycled materials like lithium, cobalt, and nickel are often cheaper than freshly mined counterparts. This cost savings can be passed on to consumers, making electric vehicles more affordable. Lower costs can lead to higher adoption rates of EVs.

The recycling industry itself creates many job opportunities. Workers are needed at various stages, from collection to processing. This leads to job growth in the recycling and manufacturing sectors. Economic growth in these areas can benefit local communities. It stimulates the economy by providing stable employment.

Recycling also reduces reliance on imported raw materials. Many of the metals used in batteries are sourced from other countries. By recycling, we can produce these materials domestically, reducing dependency on imports. This enhances national security by ensuring a steady supply of critical materials. It also keeps more money within the local economy.

The chart below shows the potential economic benefits of recycling EV batteries: Benefit Economic Impact Reduction in Manufacturing Costs Lower EV Prices Job Creation Increased Employment Reduced Import Reliance Increased National Security

Investing in recycling technologies can also drive innovation. Companies that develop advanced recycling methods can become industry leaders. These companies can profit from selling their technologies and expertise. Innovations in recycling can also lead to new business opportunities.

In summary, the economic benefits of recycling EV batteries are substantial. They include reduced manufacturing costs, job creation, and a decrease in import reliance. Additionally, investments in recycling technologies can drive further innovation. These factors contribute to a stronger, more resilient economy.

Frequently Asked Questions

Recycling electric vehicle (EV) batteries is a key topic in sustainability. Here are some common questions and thorough answers to help clarify the process and its benefits.

EV batteries contain valuable materials such as lithium, cobalt, nickel, and manganese. Recycling processes are designed to extract these elements so they can be reused. Recovering these materials reduces the need for new mining, which is beneficial for both the environment and the economy.

These metals can be purified and used in new battery production. In addition to metals, other components like plastics and electrolytes can also be recycled and repurposed, contributing to a circular economy.

Recycling EV batteries helps prevent harmful chemicals from leaching into the soil and water. Batteries contain toxic elements that can cause significant environmental damage if not disposed of properly. Proper recycling mitigates these risks and supports ecosystem health.

Additionally, recycling reduces the need for new raw materials, thus conserving natural resources and minimizing ecological disruption from mining activities. This approach helps in reducing the overall carbon footprint and promoting sustainability.

One major challenge is the complexity of battery designs, which makes dismantling and material separation difficult. Different battery types require different recycling techniques, adding to the complexity. Safety concerns, like managing the leftover electrical charge, are also significant.

Moreover, the current recycling infrastructure is not fully developed to handle the future influx of EV batteries. Innovations and improvements are needed to make recycling more efficient and cost-effective.

Direct recycling involves reconditioning battery materials without fully breaking them down. This method retains the original structure of battery components, making it more energy-efficient. It contrasts with traditional methods like hydrometallurgy and pyrometallurgy, which break down materials chemically or with heat.

Direct recycling saves resources and energy, potentially making it a more sustainable solution. However, it is still being developed and perfected, with challenges around ensuring the quality and performance of reconditioned materials.

Technology significantly enhances the efficiency and effectiveness of EV battery recycling. Advanced automated systems can safely dismantle batteries, while sophisticated chemical processes help extract metals efficiently. Innovations in AI and machine learning are optimizing sorting and separation techniques.

New research in materials science also focuses on creating batteries that are easier to recycle. These advancements collectively aim to make the recycling process more sustainable and economically viable, driving greater adoption of electric vehicles.

What *Really* happens to used Electric Car Batteries? – (you might be surprised)

Conclusion

Recycling EV batteries plays a crucial role in our journey toward sustainability. From reducing environmental harm to conserving valuable resources, the benefits are extensive. This process not only mitigates ecological damage but also supports economic growth and technological innovation.

As technology advances, the efficiency and effectiveness of recycling methods will continue to improve. This progress will pave the way for a greener future. Supporting recycling initiatives is essential for the long-term viability of electric vehicles and our planet.